Why Choose Customized Mould Inserts and Components

In the manufacturing industry, efficiency and precision are key to producing high-quality products. Customized mould inserts and components offer tailored solutions that can enhance production processes, reduce costs, and improve overall product quality. But why should you consider these over standard components? In this article, we¨ll explore the advantages of customized mould inserts and components and how they support modern manufacturing needs.From some points of view, precision plastic mould components It is the core driving force to better promote the rapid development of the surrounding markets. https://www.dghrjmmj.com

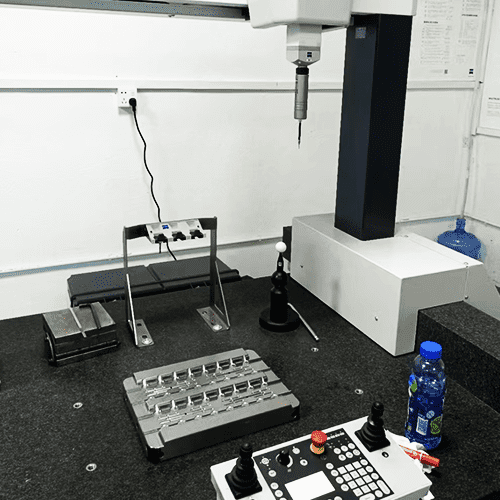

high-precision mold components.jpg

Benefits of Customized Mould Inserts and Components

1. Enhanced Precision and Fit

Customized mould inserts are designed to meet specific requirements, ensuring a perfect fit for your tooling system. By working with high-precision mold components, manufacturers can achieve tighter tolerances and consistent results, which are essential for industries like automotive, aerospace, and electronics.

2. Improved Production Efficiency

When your mould inserts and components are customized to fit your processes, you can minimize downtime caused by mismatched or faulty parts. Custom precision mould parts manufacturing ensures that every component integrates seamlessly with your machinery, reducing the risk of errors and enhancing production speed.

3. Greater Product Quality

Precision-engineered mould inserts lead to higher-quality end products. The exact specifications provided by precision mold parts suppliers help maintain uniformity across all production runs, ensuring customer satisfaction and reducing the likelihood of product defects.

4. Cost-Effectiveness Over Time

Although customized mould inserts may have a higher upfront cost, they provide long-term savings by reducing material waste, improving cycle times, and extending the lifespan of your molds. With tailored components, you can also avoid frequent replacements, saving on maintenance costs.

5. Flexibility for Specialized Applications

Standard mould components may not always meet the unique demands of specialized applications. Custom precision mould parts manufacturing allows businesses to create parts that cater to specific requirements, whether it¨s for a niche product or a complex design.

precision mold parts suppliers.jpg

Applications of Customized Mould Inserts

Customized mould inserts are widely used across industries such as:

Automotive: For creating precision parts like gears and connectors.

Medical Devices: For high-tolerance components in sensitive applications.

Consumer Electronics: For intricate designs in gadgets and devices.

Packaging: For tailored solutions in product protection and branding.